Safeguarding Intellectual Property: A Case Study of WIBU-SYSTEMS AG

WIBU-SYSTEMS AG since 1989 is known for reliable licensing and know-how protection in software and machines. The cryptography is programmed and provided to WIBU-SYSTEMS AG customers worldwide primarily on dongles. These plugs are visually similar to USB sticks. They are marked by XENO 4 laser systems with unique codes and data. By these, they remain identifiable at all times. The engraving of the dongles is done with the help of robots in fully automated plants.

The product

Machines are increasingly manufacturing individual parts these days. Manufacture and devices contain more and more know-how. Such data falling into the hands of unauthorized persons may result, amongst others, in replication. So data must be protected and tracked, and use be controlled. WIBU-SYSTEMS AG calls its technology CodeMeter. Software providers benefit, and so do machine and plant manufacturers. CodeMeter runs platform-independent. It can be used locally on a dongle or as a protective key in a network. The entire license and all secret keys are stored on the chip of a dongle. WIBU-SYSTEMS AG preferably provides USB plugs, compact or in metal or synthetic cases, capped or not capped, in standard or custom design.

The request

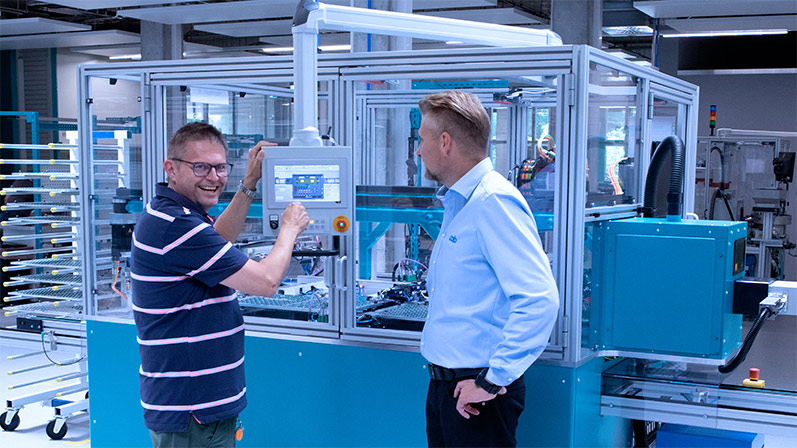

Martin Dralle provides a clear definition of what hardware must be able to do in WIBU-SYSTEMS AG manufacture facilities: “We purchase systems and plants. We specify hereto the interface, the protective circuit, the voltage, and so on. Everything else is in the hands of our partners. They provide equipment accordingly.” Mr. Dralle is a mechanical engineer. Twelve years ago, he started converting what had been purely manual dongle manufacture and marking into fully automated production systems. Today, only the custom-designed dongles are prepared by hand at the headquarters in Karlsruhe. Picking up the dongles automatically from pallets, programming, marking, testing and depositing are all exerted entirely mechanically with the help of robots amid protective glass.

“With regard to cab lasers,” says Mr. Dralle, “the basic request was to apply an engraving to the metal or synthetic parts. These have a basic standard design. Graphics, texts, parameters, and data are to be applied specific to customers.” Manuela Burkert is responsible for purchasing, production, and logistics at the company. “Each connector has its own serial number,” she adds. “We mark these by means of a DataMatrix code. By this, we can track each part, representing traceability. This is very important for our customers.”

The application

In the first step, dongles are automatically fed on pallets to the manufacturing line. They are then picked up by a robotic gripper, aligned, and set onto a programming station. A second gripper picks up an already programmed plug and transfers it to the next workstation, the marking laser. The shaft of the laser station opens. The robot with its vacant gripper removes the plug that has already been engraved by laser and with its second gripper puts into place the one that still needs to be marked.

The entire marking, from opening the shaft to engraving and reopening the station, takes just twelve seconds. The dongles can be marked on a maximum of three sides. The manufacturing process is completed by the robot returning the marked dongles to their initial spots on a pallet. No dongle leaves the manufacturer without testing. Only products of perfect quality are set back onto the pallets. About one million dongles per year are manufactured by WIBU-SYSTEMS AG in this way.

The laser

XENO 4 fiber lasers by cab are particularly economical if top markings are required in conjunction with high performance and long life cycles of the marking system. In these, the core of a glass fiber forms the laser-active medium. Optimally matched to the application, they operate highly efficient and require less energy than, for example, a CO2 laser.

XENO 4 consists of a control unit with a beam source and a scan head linked to the beam source. The system is provided with cablase software ex-factory. To bundle the laser beam, the scan head is equipped with a planospherical lens. By this, a specified marking field can be covered. All markings, such as part IDs, article numbers, serial numbers and customer numbers, manufacture orders or processing steps, resist to smear, acids or alkalis, solvents, heat or cold, and wear.

Video of the operation:

https://www.cab.de/media/videos/cab_wibu_en.mp4